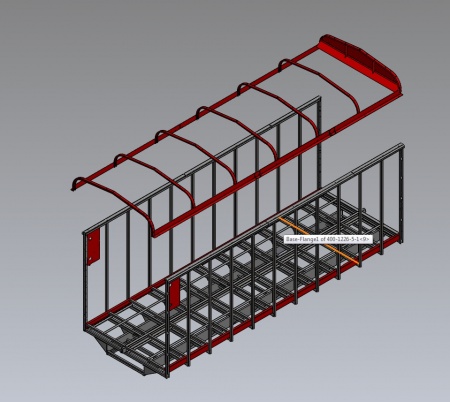

RTX200 Front & Rear Unload Forage Box

Model # RTX220 / RTX222 / RTX224 / RTX226

The Meyer RTX200 Series Front & Rear Unload Forage Box features a 7'5" inside width, HD all steel frame, high speed - variable drive, HD bevel geardrive, poly floor, high sides, 4 beaters, rear gate delay and more! Wagon, Cart or Truck Mount models are available. It offers more capacity, more speed and more options than any other forage box on the market! RTX200's are standard as an open top but also offer a roof option. Hydraulic drive packages are also avaiable.

PHOTOS

VIDEOS

RTX200 Series Front / Rear Unload

Meyer Moves Forage Faster

FEATURES